Gems of Stainless Steel Valves – Resilience and Corrosion Resistance Unleashed

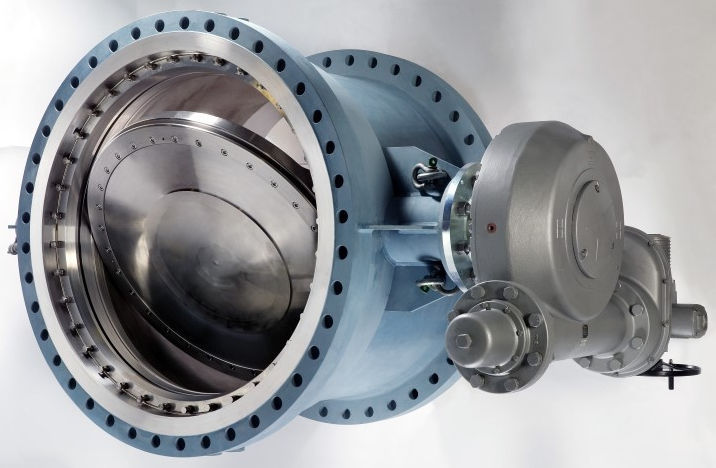

Stainless steel valves are true hidden gems in the world of industrial engineering, boasting unparalleled resilience and corrosion resistance that are unmatched by many other materials. These valves are a marvel of modern metallurgy, combining the strength of steel with the unique properties of chromium to create a material that can endure the harshest conditions with ease. One of the key attributes that make stainless steel valves stand out is their exceptional resilience. Resilience refers to a material’s ability to withstand stress, pressure and external forces without yielding or deforming. Stainless steel valves excel in this regard, making them ideal for applications that involve high-pressure fluids or gases. They can maintain their structural integrity under tremendous force, ensuring the smooth and reliable operation of various industrial systems.

However, the true magic of stainless steel valves lies in their remarkable corrosion resistance. Corrosion, the gradual deterioration of materials due to chemical reactions with their environment, is a pervasive problem in many industries and pop over to these guys https://anixusa.com. Traditional valves made from other materials are susceptible to corrosion, leading to costly repairs and replacements. Stainless steel valves, on the other hand, are practically impervious to corrosion, making them an invaluable asset in environments with aggressive substances or extreme temperatures. The secret to the unrivaled corrosion resistance of stainless steel valves lies in the presence of chromium. Chromium is a vital component of stainless steel, forming a thin, invisible oxide layer on its surface when exposed to oxygen. This passive film acts as a shield, protecting the underlying steel from corrosive elements such as water, acids and chemicals. As a result, stainless steel valves can function flawlessly in corrosive environments, even those subject to saltwater exposure, which is particularly damaging to most other materials.

The durability and longevity of stainless steel valves contribute to significant cost savings for industries. Since these valves can endure harsh conditions without corroding or deteriorating, they require minimal maintenance and have extended service life. This reduced need for frequent replacements and repairs translates to lower downtime and operational costs, enhancing overall efficiency and productivity. Moreover, the inherent hygienic properties of stainless steel make these valves indispensable in applications involving food, beverage and pharmaceutical industries. The smooth and non-porous surface of stainless steel prevents the accumulation of bacteria, making it easy to clean and maintain strict sanitation standards. In conclusion, the resilience and corrosion resistance of stainless steel valves are indeed unleashed hidden gems in the realm of industrial equipment. With their exceptional ability to withstand pressure, stress and aggressive environments, these valves play a crucial role in ensuring the smooth and reliable operation of various industrial processes. Furthermore, their resistance to corrosion and hygienic properties make them the preferred choice in industries where purity and sanitation are paramount. As technology and metallurgical advancements continue, stainless steel valves will undoubtedly remain at the forefront of innovation, setting new standards for performance, reliability and longevity in the industrial world.

The durability and longevity of stainless steel valves contribute to significant cost savings for industries. Since these valves can endure harsh conditions without corroding or deteriorating, they require minimal maintenance and have extended service life. This reduced need for frequent replacements and repairs translates to lower downtime and operational costs, enhancing overall efficiency and productivity. Moreover, the inherent hygienic properties of stainless steel make these valves indispensable in applications involving food, beverage and pharmaceutical industries. The smooth and non-porous surface of stainless steel prevents the accumulation of bacteria, making it easy to clean and maintain strict sanitation standards. In conclusion, the resilience and corrosion resistance of stainless steel valves are indeed unleashed hidden gems in the realm of industrial equipment. With their exceptional ability to withstand pressure, stress and aggressive environments, these valves play a crucial role in ensuring the smooth and reliable operation of various industrial processes. Furthermore, their resistance to corrosion and hygienic properties make them the preferred choice in industries where purity and sanitation are paramount. As technology and metallurgical advancements continue, stainless steel valves will undoubtedly remain at the forefront of innovation, setting new standards for performance, reliability and longevity in the industrial world.